Innovative and affordable mixing solutions-Pioneering Efficiency for Seamless Solutions

A Rotor Stator Homogenizer is a powerful device employed in various industries for the efficient mixing, emulsifying, dispersing, and homogenizing of substances. Its innovative design and working principle make it a cornerstone in the production of numerous products across pharmaceuticals, food and beverage, cosmetics, chemical processing, and more.

The primary function of a Rotor Stator Homogenizer is to break down, blend, and emulsify substances that are otherwise immiscible or challenging to combine uniformly. This homogenization process results in the creation of stable and consistent mixtures or emulsions. It's instrumental in achieving particle size reduction, ensuring uniform distribution of components, and enhancing product quality.

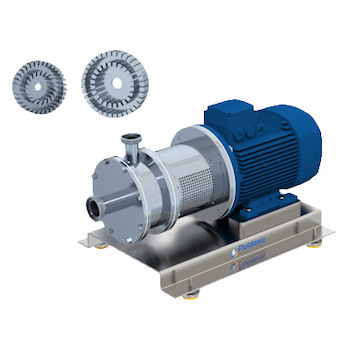

The homogenizer comprises two main components - a rotor and a stator. The rotor is a high-speed spinning shaft with precision-engineered blades or teeth, while the stator is a stationary surface with complementary configured channels or grooves.

When the rotor rotates at high speeds, the fluid or substance is drawn into the narrow gap between the rotor and stator. This action generates intense shear forces and turbulence due to the close proximity and high-speed interaction between the rotor and stator elements.

Intense Mixing and Disruption:

As the substance passes through the narrow gap, it experiences rapid changes in velocity and direction. This high shear action causes intense mixing, breaking down larger particles into smaller ones, dispersing them uniformly throughout the mixture.

Uniform Homogenization:

The repeated mechanical shearing and impact between the rotor and stator components lead to the creation of microdroplets or smaller particles, resulting in the thorough homogenization of the mixture. This process ensures consistent quality, stability, and desirable properties in the final product.

The versatility of Rotor Stator Homogenizers makes them indispensable across various industries:

- Pharmaceutical: Formulation of medications, vaccines, and pharmaceutical suspensions.

- Food and Beverage: Production of emulsions, dressings, sauces, and dairy products.

- Cosmetics: Manufacturing creams, lotions, and personal care products.

- Chemical Processing: Emulsification of polymers, paints, and various chemical compounds.

In summary, the Rotor Stator Homogenizer's efficient working principle and functionality enable it to play a crucial role in achieving precise mixing, uniformity, and consistency in a wide array of industrial processes, contributing significantly to the quality and performance of end products.